IDRAL concentrates in-house the study and design of new products, mechanical processing, testing and assembly carried out with specially designed equipment, while casting and hot moulding, cleaning and galvanic finishing are outsourced.

The quality and materials used in the production of Idral fittings, which are constantly monitored and tested, are proven by various international certifications attesting to their high standard, including ISO 9001:2008, EN 12164 and EN12168:98 for turned items, EN 12165 for moulded items and EN1982:2001 for all foundry production.

IDRAL's in-house production system encompasses several processing stages:

1. Mechanical processing

Cast or moulded parts undergo mechanical machining on multi-axis CNC machining centres.

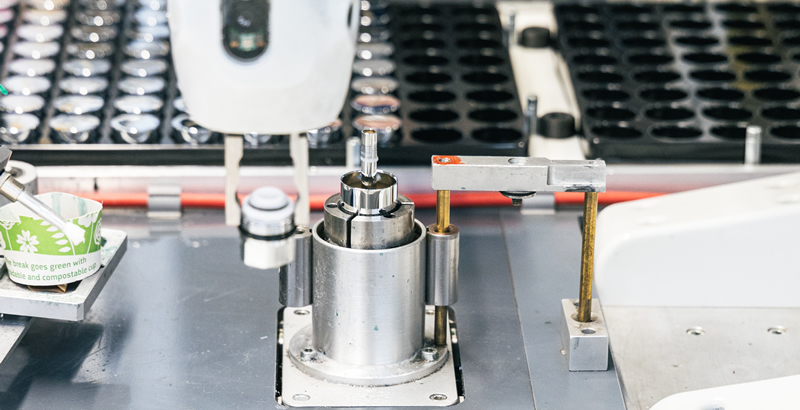

2. Single-spindle machining centre

Single-spindle machining centres are a flexible, productive, reliable and quality-assured machining system.

3. Components

Numerous components are manufactured from the BRASS BAR by in-house machining on automatic lathes.

4. Finishing processes

Components machined in the machine shop are sent to outsourced surface finishing processes of cleaning, chrome-plating, painting.

5. Laser marking

Laser marking can be used to quickly produce extremely precise markings that can be customised at the customer's request.

6. Assembly

Assembly can be automatic or manual, depending on the form and function of the product.

7. Aesthetic checks

Aesthetic checks are also carried out during assembly to promote the product to the next production stage or for sale.

8. Dimensional checks

Dimensional checks are carried out on 100 per cent of the components to ensure correct appearance and dimensional compliance so that they can be assembled correctly and perform consistently.

9. Functional checks

Functional/performance checks by air or water are performed on 100% of production and guarantee the quality of the individual finished product.

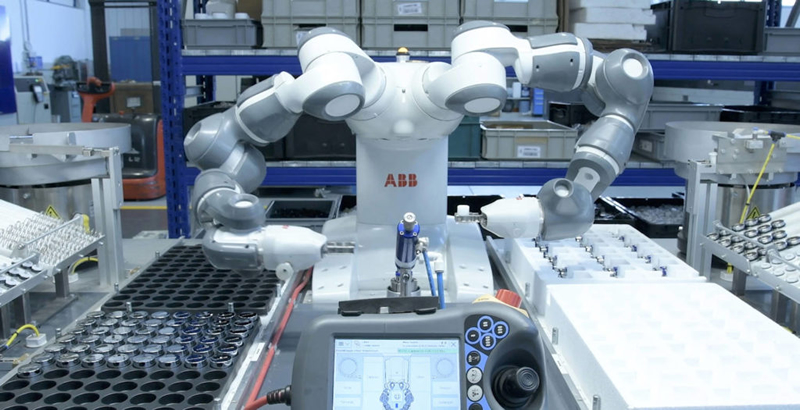

10. Vertical warehouse

The new automatic warehouse for storing all components and the help of robots makes it possible to work in real time, i.e. 'on request', and to adapt the product to the customer's needs.